|

CNC DECKEL FP1 | home |

A while ago I visited a deckel owner in

Germany. The first thing that struck me was that a Deckel FP1 is quite

a category smaller than a MAHO SK250. The machine is used for the fabrication of turbine-engineparts. That is turbine engines for model airplanes. Partly the engines are made of off-the-shelve turboloader parts and partly the parts are made by himself. The turbines have a thrust-power of 16 kg. Click the pictures to enlarge. |

|

|

|

| The software runs on a pentium

II machine. In the beginning a 486 was used but the maximum frequency

depends on how fast the computer is and a 486 caused the machine to run

too slow. In the cabinetdoor are some controls mounted which are used for a manual override. |

|

|

|

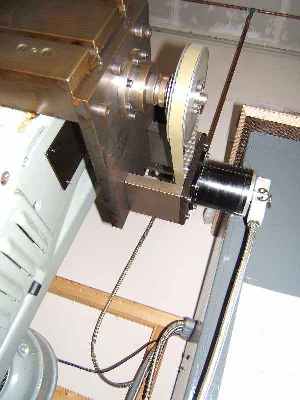

All motors are from Nanotec in Germany. I believe the type-codes have altered but here is an explanation of the code. All shafts have the same diameter (20 mm) and the same feed (5 mm). All pullys have the same gear-ratio I measured the outer pully diameter 37 and 127 mm. I think the belt thickness is about 3.5 mm, this leaves 30 and 120 mm, so the rate must be 1:4 |

|

motor specs:

|

shaft specs: - nut driven - dia 20 mm - feed 5 mm - belt width : 16 mm - pullyrate: 1:4 |

|

|

|

|

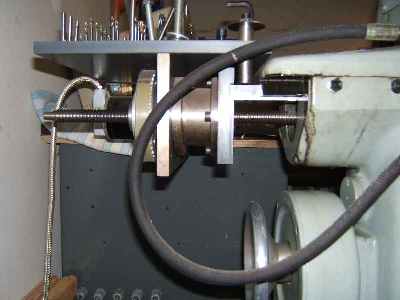

motor specs: |

shaft specs: - nut driven - dia 20 mm - feed 5 mm - belt width: 16 mm T10/660 - pullyrate: 1:4 |

|

|

|

|